Rapid Prototyping Services

WJ Prototypes provides competitively priced, quality parts; quickly. Whether your project is a quickly needed small quantity prototype job or your annual production run; WJ Prototypes can help.

- No MOQ

- Quality & Precision

- Fast Turnaround

- Rapid Prototypes

- Low-Volume To Mass Production

- Global Delivery

Serving Clients Worldwide From China.

Dedicated Project Manager.

On-Time

Delivery Rate

Yield

Customer

Satisfaction Rate

Satisfied Customers

Our Certifications

All certifications are held at our respective factory locations and can be verified upon request.

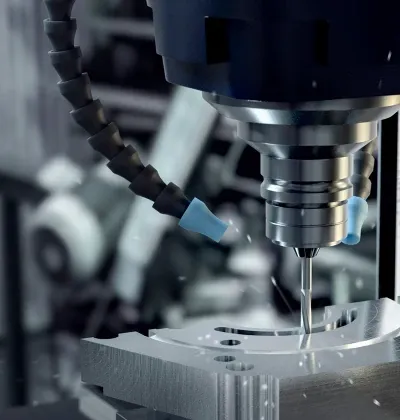

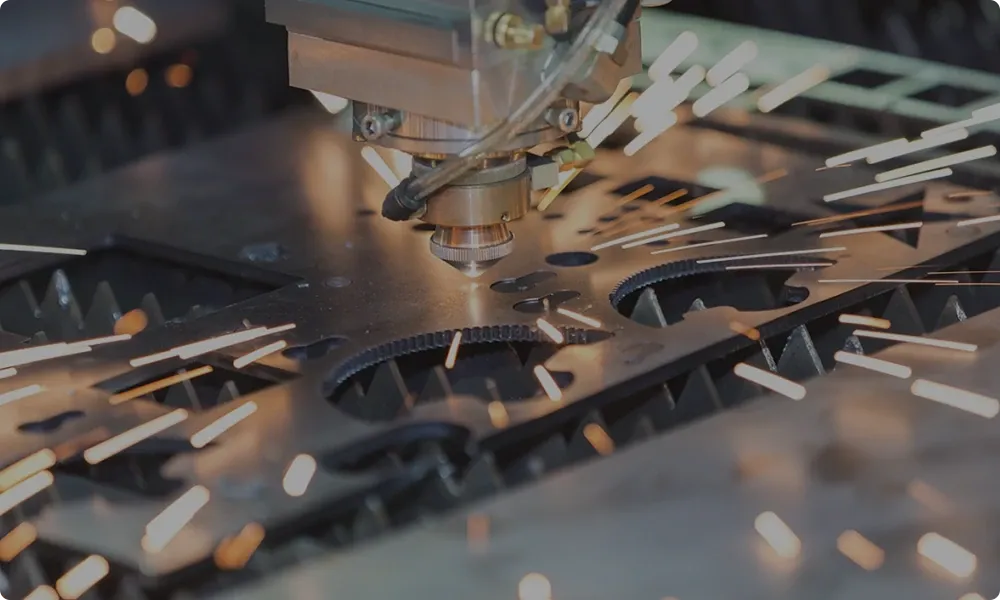

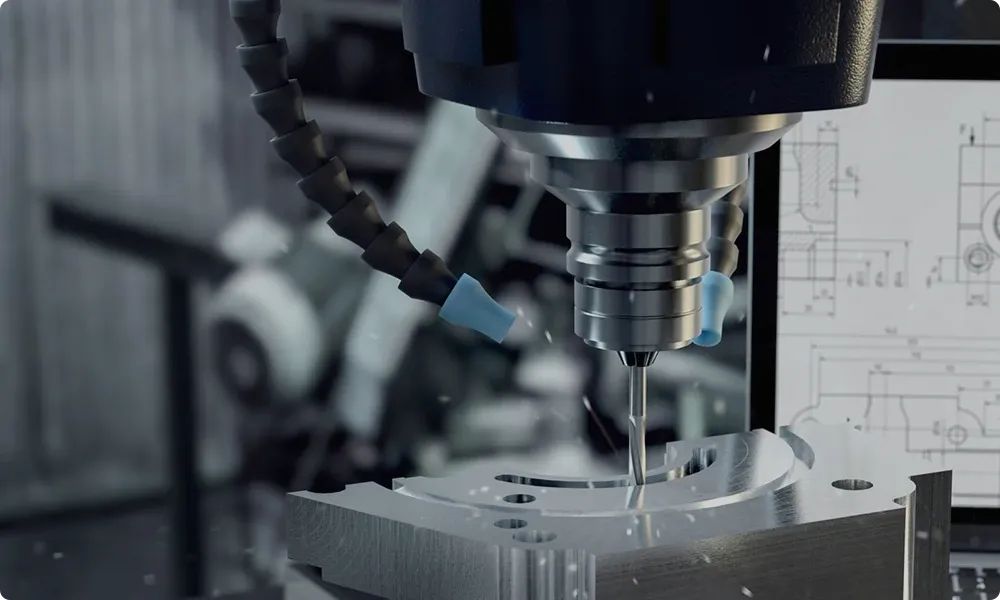

Our Manufacturing Capabilities

Are you looking for a professional prototyping service to help actualize your ideas and assist with product development? Then you’ve come to the right place. WJ Prototypes provides excellent quality, quick turnaround, and cost-effective rapid prototyping services to customers across the world. Equipped with cutting-edge prototyping and production manufacturing technology, advanced industrial-grade equipment, and an expert team of engineers. WJ Prototypes can bring your idea from design to the market in just a few days. We’re excited to start working with you! If you have finished prototyping and are ready to move forward to production, please take a look at our low volume manufacturing service.

Include SLA, SLS, MJF, DMLS, and more

30 plastic and metal materials in a range of finishes

30 years of additive manufacturing expertise

Machined parts in as fast as 1 day

Cost-efficient machined parts at higher volumes

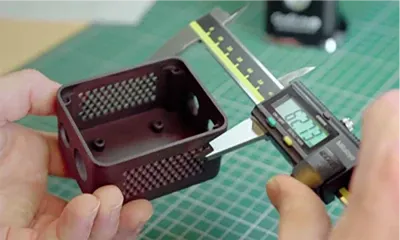

Tolerances down to ±0.001 in. (0.020mm)

interactive manufacturability feedback

Six sheet metal materials including aluminum, stainless steel, steel, brass, and coppe

100+ plastic, elastomeric, and silicone rubber materials

Low-volume molding up to 100,000+ parts with volume pricing available—no MOQ required

Capable of producing large parts

Superior surface finish to injection molding

Is suitable for producing complex parts.

Offers repeatable, accurate results with efficient production.

Why choose our rapid prototyping services?

Excellent. Efficient. Economic.

No MOQ

We are flexible for one-off prototypes and low-volume parts. No matter the size of your order, we can handle it.

Competitive Pricing

We have built up an efficient rapid prototyping system which allows us to offer competitive prices that can match any offer.

Rapid Turnaround

Our capacities allows us to finish your rapid prototyping projects in days.

Experienced Engineers

Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

Tight Tolerances

We service the aerospace and medical industries and can produce precise parts with tight tolerances.

Wide Range of Materials

We serve a wide range of clients and can offer a variety of rapid prototype materials and finishes.

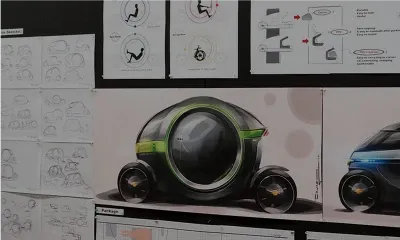

Automobile

Fast-track development for electric vehicles, charging devices and other automotive innovations.

Learn More →

Aerospace

Produce aerodynamic parts for aircraft, drones, satellites and rockets with AS 9100 certification.

Learn More →

Industrial

Meet the growing need for connected hardware while still supporting legacy equipment and machinery with custom parts.

Learn More →

Medical Devices

Fast-track development for electric vehicles, charging devices and other automotive innovations.

Learn More →

Robotics

Manufacture parts requiring highly cosmetic features for gaming, audio, video and smart home products.

Learn More →Types Of Rapid Prototype

Used by customers across many industries, rapid prototyping encompasses different technologies and materials. It also covers different kinds of prototype, including visual-only prototypes and functional prototypes used for testing a part’s performance.

Concept model

A proof-of-concept prototype is the earliest and simplest kind of prototype, used to convey the basic idea of the part. Concept models are typically kept internal and may go through several iterations.

Display prototype

A display prototype (or looks-like prototype) is a more developed prototype with a focus on its cosmetic aspects. The prototype should resemble the final part as much as possible, though it may not function fully or at all.

Functional prototype

A functional prototype is built to behave like the end-use part. This enables the designer to carry out any necessary mechanical testing on the prototype to ensure its correct function.

Pre-production prototype

A pre-production prototype or factory sample is the last kind of prototype used before production. It is typically used to validate the chosen mass manufacturing process, ensuring that the manufactured part will perform as expected.

How to Work With Us

01

Get An Instant Quote

02

Confirm Specifications

03

Manufacturing Begins

04

Parts Are Shipped

Get An Instant Quote

undefined

Testimonials / Satisfied Customers

Dorothy

Buyer at Leading Energy company

WJ Prototypes is Great!

“We’re glad we recently added WJ Prototypes to our AVL. You guys are always quick and friendly and all the Machining jobs we have sent have gone smoothly!”

Thomas

Engineer at Robotics Company

Our No.1 source for CNC parts

“We had a time sensitive Sheet Metal enclosure with fairly strict cosmetic requirements. WJ Prototypes came through for us and the parts looked great. The full build turned some heads at our Trade Show!”

Marc

Buyer at Electric Car Company

Great prices, lead times, and quality of work

“You guys are one of the easiest job shops I’ve worked with the last 10 years. You are responsive and competitive. We’ve appreciated the awesome work!”

Video Display

High Quality Parts Every Time

Quality assurance

From factory audits to part inspections, we follow strict processes to ensure your parts always meet the highest quality standards.

IP protection

We take every measure to ensure the protection of your IP, which is why 27% of Fortune 500 companies trust us with their projects.

Certifications

Our manufacturing partners have all the necessary certifications for your project's needs (ISO 9001, ISO 14001, IATF 16949, ISO 27001).

Frequently Asked Questions

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by layering material on top of each other using a computer-controlled printer. It allows for the production of complex and customized designs.